QC Press Works is in the Quad Cities and located in Davenport, IA and specializes in deep draw and transfer die stamping of parts. Our facility utilizes multiple hydraulic and mechanical industrial presses dedicated to metal stamping and range from 1250 Ton to 100 Ton. Our skilled workforce has years of experience in producing metals stampings for a wide range of OEMs and manufacturers representing a vast range of industries.

We utilize several stamping processes depending on the product or application of the stamping required. These include Deep Draw Process, Hand Transfer Die Stamping, and Hot Forming. Each process is described below.

Deep Drawing is the process of taking a steel blank and stamping it with a die repeatedly or transferred to another die for additional stamping until the desired shape is achieved. The advantages of Deep drawn parts is that the part can be made in one piece thus reducing the need for additional assembly. Also, a one-piece part has a seamless construction making it ideal for parts that need to be watertight or airtight like a fuel tank for example.

Deep drawing also results in a stronger part because of the amount of force applied to the metal during the forming process therefore the fundamental structure of deep drawn metals is often highly compressed into a very hard crystalline structure. Another important feature is our presses have air cushions to help push the material back out once it gets drawn both for efficiency and reducing possible damage to the part.

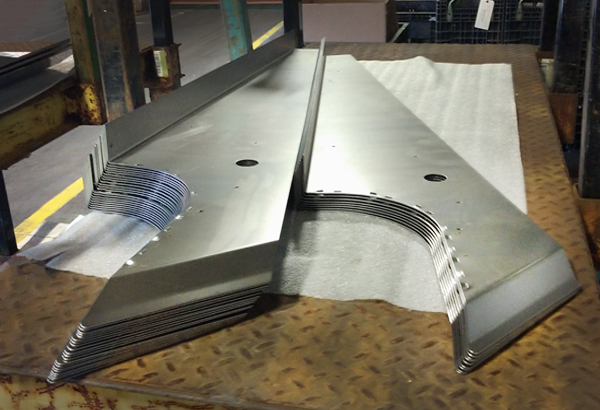

Transfer Press Stamping is a great alternative stamping method for production stampings often having a of lower tooling costs. A transfer press tool can use a single die and one station with the press or have sequential stations. The transfer press process begins with a strip of metal fed into the first station where the blank for the component is cut from the strip. The blank is then transferred manually to various forming stations until the final shape is complete.

We use hand transfer stamping to manufacture deep-draw parts and components. Because there is no metal strip attached to the part, the stamping press can punch as deep as the raw material will allow.

Quad Cities Metal Stamping can hot form metal using our industrial oven to bring the temperature of the steel to 2000 degrees. Some processes or parts (like thick steel parts) require heating to form them to the required shape. We currently produce several parts using hot forming that include linkages and couplings for heavy equipment manufacturers that necessitate hot forming for achieving strength and shape within the tolerances of the part.

Quad Cities Metal Stamping specializes in service parts with our stamping presses can make a wide range of quality stampings ranging from fuel tanks to skid steer doors.

Double crank, 14" stroke, 35" shut height, 62" x 82" bolster and 42" x 74" ram. Equipped with 9" ram filler block.

Eccentric drive, 18" stroke, 34" shut height, 60" x 96" ram and 60" x 96" bolster. Two cushions with 45 tons capacity each and with 9" stroke.

Double crank, 8" stroke, 20" shut height, 41" x 60" bolster and 30" x 55" ram. 31-ton air cushion with 4" stroke.

Double crank, 8" stroke, 20" shut height, 41" x 60" bolster and 30" x 55" ram. 31-ton air cushion with 4" stroke.

12" stroke and 42" x 48" bolster.

54” stroke, 20” shut height, 72” x 144” ram. 48” x 56” center cushion with 265 tons capacity and two end cushions of 48” x 32” with 157 tons capacity each. Stroke of all cushions is 18". Equipped with two end resistance cylinders with 400 total tons for use on blanking operations.

42” stroke, 18” shut height, 66” x 96” bolster and 60” x 96” ram. 47” x 35” center cushion with 100 tons capacity and two end cushions of 47” x 19” with 50 tons capacity each. Stroke of all cushions is 18". STRIPPIT – 40 ton, numerically controlled, 30” throat, single station.