Glass transport racks are specialized steel racks designed to safely move and store flat glass sheets, typically used in the glass handling industry. NSMC has been providing some of the country’s leading glass manufacturers with custom fabricated glass racks. Our durable construction and full weld seam joints are just two reasons why so many companies buy and buy again from us

There are two common style of glass racks, A-Frame and L-Buck racks each designed for specific applications. All of our racks can be stationery, forklift accessible, or mobile with the addition of heavy duty castors.

A-Frame Racks:

These freestanding racks have two upright sides connected by a crossbar at the top, and they may or may not have shelves. A-frame racks are often used to store or transport large sheets of glass inside a glass manufacturing plant or warehouse.

L-Buck Glass Racks:

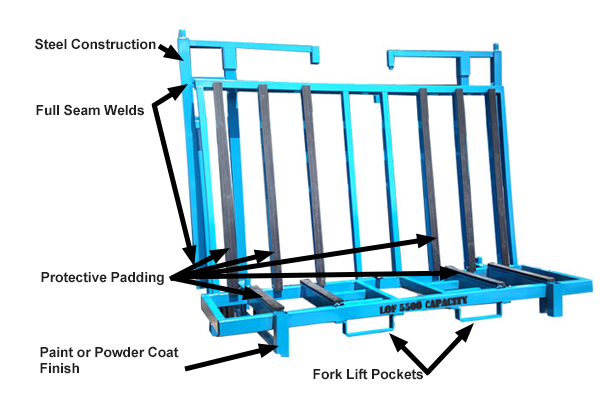

An L-buck glass rack is a type of metal storage unit designed specifically for holding large, flat sheets of glass securely. They are typically L-shaped, with one long side and a shorter side that provides stability and secures sheet glass for storage or moving from one area to another.

Space efficiency:

L-bucks take up less floor space because they have a single upright back. This can be crucial in tight storage areas. Stability: The L-shaped design of L-bucks offers a wider base of support, which can be advantageous for storing particularly heavy or thick glass sheets.

Stability:

The L-shaped design of L-bucks offers a wider base of support, which can be advantageous for storing particularly heavy or thick glass sheets.

Our glass transport racks are custom fabricated to meet your size, load requirements and specifications. We also offer rack design services to help you create a custom rack that will meet your requirements.

Our racks feature rigid steel frames, full seam welds (not stitch welded to reduce costs) and have optional dunnage and security features to secure and protect the glass. Our quality control and assurance inspects each unit we build throughout the entire process to eliminate any issues. We also offer heavy-duty swivel casters to improve workflow.

We also offer complete finishing of your rack with paint or powder coating in a wide range of colors (even specific brand colors) to enhance and add to the durability of your racks in even the harshest environments. We complete the process by adding screening or stenciling of your company name, inventory number or department to the frame.

For over 18 years NSMC has provided customers with quality durable racks that offer the strength and security of lifting thousands of pounds of glass panels at a construction site or within a manufacturing facility. Read our case study on how important full seam welds are in the glass manufacturing industry.