Our CNC machining services use computer numerical control machines. These machines shape materials with exact precision. They follow pre-set digital instructions to create parts. This manufacturing process works well for many jobs. We make CNC machined parts for a wide range of applications.

CNC machining removes material from raw parts. Computer-controlled tools cut away excess material. This method beats manual work. CNC machines follow exact digital steps. This gives you high accuracy and consistent results every time.

Our high precision services let you outsource your CNC machining projects. We promise quality work and on-time delivery. This lets you focus on your main business goals. We handle small prototype jobs and custom parts. We also take on medium production runs.

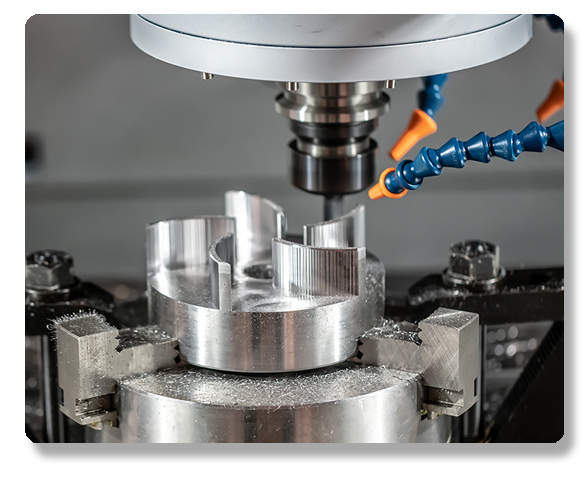

We use rotating cutting tools to remove material. The workpiece stays still while tools move around it. The part sits on a table that moves in different directions. This lets us cut from many angles. CNC mill work is perfect for complex shapes. We make slots, holes, and detailed features.

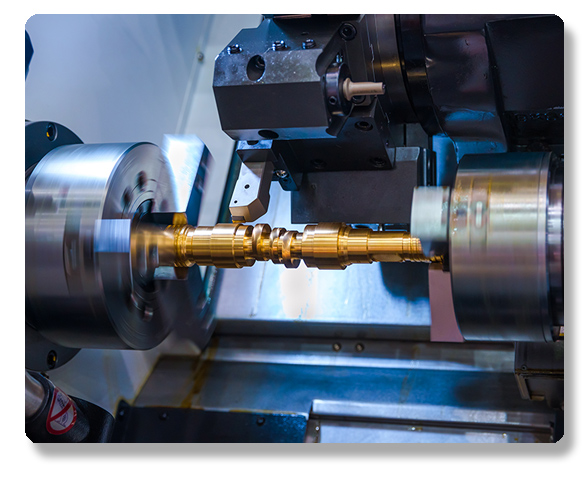

The workpiece spins at high speeds during CNC turning. A single cutting tool stays in place and cuts the spinning part. This process works great for round parts. We make shafts, bushings, and pins this way.

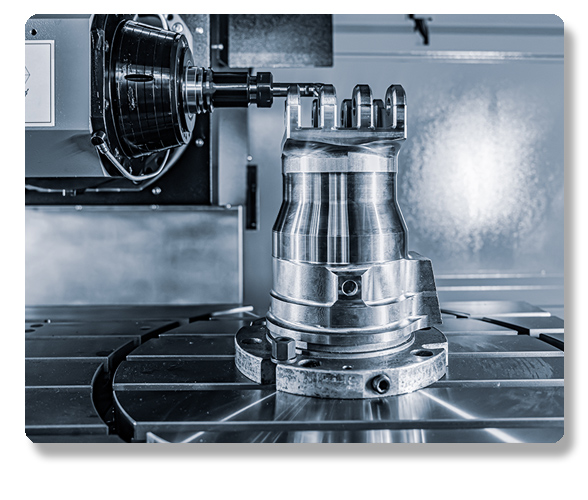

This advanced method moves tools in five directions at once. The tool moves along three straight lines (X, Y, Z axes). It also rotates in two directions (A and B or B and C axes). This extra movement lets us cut very complex shapes. We can make detailed contours in one setup. This cuts down on multiple setups. It also improves accuracy and surface finishes. This method works well for parts with deep pockets. It's great for parts with angled features. We use it for turbine blades and medical implants.

NSMC and its partners have served the Davenport, Iowa and Quad Cities region for over 25 years. We provide CNC machining services to many top manufacturers. Our clients include farm equipment makers. We also work on government and military projects.

We continue buying new equipment to boost productivity and quality. Our team includes skilled and experienced machinists. We deliver high quality and accuracy. Our work is consistent and repeatable. This shows in our high customer retention rate. We deliver parts on time, every time.

We know that quality machining is just the start. Customer service and project management matter too. We want to be more than just a machining provider. We aim to be your trusted supply chain partner.

CNC machining works with many different materials. Metal choice matters a lot. The metal's properties affect how easy it is to machine. They also affect the final part's performance. Material choice affects cost and complexity too. Here are the common metal types we work with.

Properties:

Aluminum is one of the most popular metals for CNC work. It has a great strength-to-weight ratio. It resists corrosion well thanks to a natural oxide layer. It conducts heat and electricity well. It's also very easy to machine. The metal is soft, so we can remove material quickly. This helps cutting tools last longer.

Applications:

We use aluminum for aerospace parts and automotive components. It works well for electronics and consumer goods too.

Properties:

Stainless steel fights corrosion extremely well. It has at least 10.5% chromium content. This gives it high tensile strength and durability. It also looks good and handles heat well. But it's harder to machine than aluminum. We need stronger tools and slower cutting speeds.

Common Grades:

• 303

• 304/304L

• 316/316L

• 17-4 PH

Applications:

We make medical instruments and food processing equipment. Stainless steel works for automotive parts and marine components. We also use it for industrial machinery and aerospace parts.

Properties:

Steel alloys offer many different properties. This depends on what's mixed into them. They can be very strong and hard. They resist wear well and stay tough. They cost less than stainless steel or titanium.

Common Grades:

• 1018 (Low Carbon Steel)

• 4140 (Chromium-Molybdenum Steel)

• A36 (Structural Steel)

Applications:

We make automotive parts like gears and shafts. Steel works for construction and heavy machinery. We also use it for tooling and structural parts.

We offer rapid prototyping for quick part development. Our online CNC machining service makes ordering easy. Get an instant quote through our system. We also provide an online quote option for fast pricing. Our 3-axis mills handle standard machining jobs. For complex work, we use advanced 5-axis machining. This gives us high performance results. We work with materials that need chemical resistance. Our parts have excellent strength. Our contract manufacturing services help with larger projects. We maintain ISO certification for quality assurance. This ensures consistent results for every CNC machining project. Contact us today to discuss your CNC machining service cost. We'll help you find the best solution for your needs.

NSMC invites you to contact us about your project or just to talk with an expert about how we may best serve your company.

Contact Us