Many of our customers choose to outsource their laser cutting needs to us because it allows them to access specialized technology, expertise, and capacity without the significant capital investment, ongoing operational costs, and management overhead associated with establishing and running an in-house laser cutting department.

They also choose NSMC because of our consistent quality and delivery of their production orders on time. We focus on precision cutting to our customers’ specifications along with customer service and project management to not only deliver parts with clean cut edges but also manage and communicate your project status. We believe that being a reliable vendor is both quality and knowing your work is completed on time.

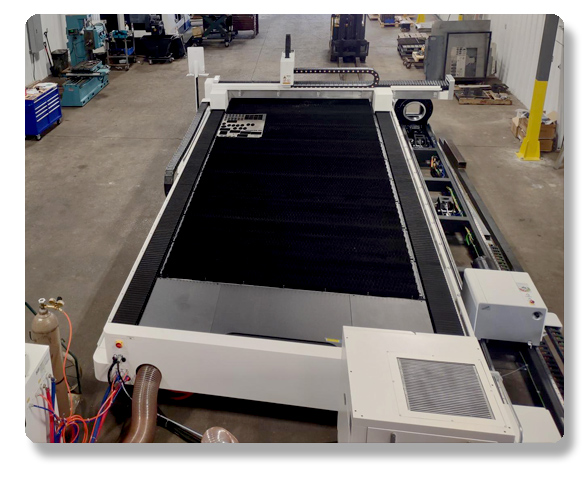

Our state of the art BODOR AT6 - 6000-watt fiber laser cutting system offers significant power for cutting a wide range of metal types and thicknesses.

Laser Power: 6000 Watts

Working Area: 8ft. x 20ft bed.

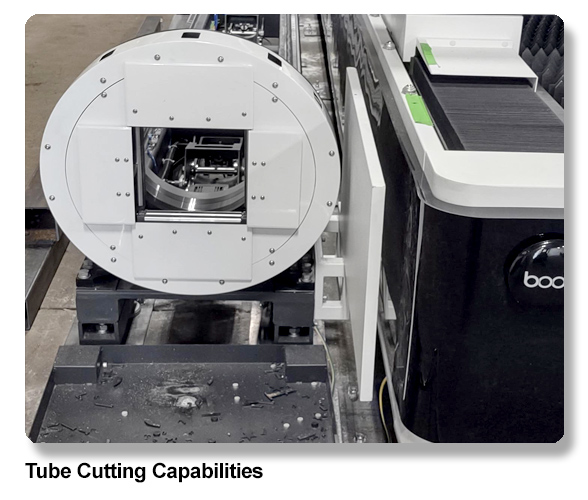

5 Axis Tube Cutting Dimensions: Up to 20ft. long and up to 9in tube diameter

Maximum Cutting Thickness:

Carbon Steel: Up to 20-25mm

Stainless Steel: Up to 12-16mm

Aluminum: Possibly Up to 10-14mm

Maximum Positioning Speed: 80-150 m/min.

Acceleration: 1.5G

Positioning Accuracy: ±0.05 mm/m

Repositioning Accuracy: ±0.03 mm.

We receive many questions regarding our laser cutting service and share them with you to help you answer your questions.

Answer: Laser cutters are versatile and can process various metals, including steel (mild, stainless), aluminum, brass, copper, titanium, and certain alloys. The type and thickness of metal that can be cut effectively depend on the laser's power and type.

Answer: Laser cutting offers high accuracy, typically achieving tolerances within ±0.005 inches (±0.127 mm) and sometimes even finer. The narrow kerf of the laser beam contributes to this precision.

Answer: The cost of laser cutting depends on factors like material type and thickness, part complexity, and production volume. While the initial investment in equipment can be high, laser cutting can be cost-effective for many applications due to its speed, precision, minimal waste, and reduced need for secondary finishing.

Answer: Laser cutting typically produces a smooth, clean edge with minimal or no burrs. This often eliminates the need for secondary finishing processes, saving time and cost.

NSMC invites you to contact us about your project or just to talk with an expert about how we may best serve your company.

Contact Us