Whether you run a warehouse or a manufacturing facility you know that moving materials, parts, and products around can be challenging. Sure, plastic containers are popular but what about moving heavy parts or parts that are bulky or are high temperature parts? Custom steel containers offer several unique advantages that can reduce your costs and improve your production flow.

Benefits of Wire Mesh Containers:

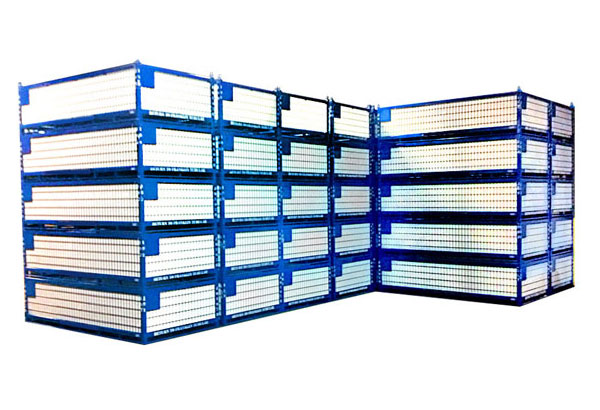

First and most important is that we fabricate each container to your specifications or our design department can help determine your requirements and create drawings for productio. Next we can add features and options like gates, placard holders and more and then powder coated in your choice of colors.

- These containers are made to fit your operations not the other way around.

- High-grade teel posts and frames enabled the uits to carry more weight.

- Units can be stacked allowing you more floor space for other needs.

- Units can have dunnage applied to protect or allow part orientation .

- Wire mesh sides make inventory and part identifcation easier .

When Your Product Demands a Stronger Container

Steel wire mesh containers are stronger and more durable than most alternatives, unlike industrial plastic containers they can be custom manufactured to your specifications and requirements. So, factors like maximum weight and capacity and even the footprint size can be tailored to fit your production process and space requirements.

Steel containers offer better durability and performance standing up to repeated loading and unloading of heavy parts, forklift strikes, and the abuse from an industrial environment. They are stackable, forklift compatible, and require little to no maintenance, saving you time and money in the long run.

NSMC Custom Fabricated Containers

NSMC provides custom steel containers to meet your application requirements and offers advantages and benefits over the competition. As the manufacturer, we have control over the quality and process from raw materials to our own in-house fabrication and welding lines to final finishing of paint or powder coating under one roof. We can also provide customization like drop gates and label holders. Since 1994 John has been supplying OEMs and manufacturers across the United States in a wide variety of industries from glass manufacturers to farm equipment manufacturers and government facilities.

Browse Our Portfolio Gallery