For over 25 years NSMC has served manufacturers and OEMs with world class returnable shipping racks, stacking racks, industrial wire baskets and carts. Because we have an extensive range of heavy metal fabrication equipment (needed for producing racks and carts) we have the capacity and experience to serve our customers with contract metal fabrication services to meet their production demands. We can produce their parts and components to their specifications and schedules through our implementation of lean manufacturing principals as well as our fabrication.

Click Listing For Details

Many companies and OEMs are turning to contract manufacturing services to source some of their production needs because it is often more cost effective to have another company produce parts or components then to do them internally. By reviewing and understanding the tolerances, dimensions, and quality checks, NSMC can replicate the manufacturing process to meet the demands of the manufacturer while maintaining the consistency and quality of the parts made. Further understanding of inventory needs and delivery dates can be accomplished through a lean manufacturing process that ensures the metal parts are produced on time and to the level of quality needed. Usually this can be accomplished more efficiently and reduced costs then the manufacturer can produce the part

332116, 332313, 332322, 332439, 332510, 332710, 332721, 321920, 332992, 332993, 332994, 332995, 332999, 811121, 325510, 332812, 336992, 336399

NSMC will weld as per your print specifications or highest possible standard called for, we offer MIG, TIG, and STICK Welding and will soon be offering Laser Welding. NSMC coordinates work cells to meet demand and shipping requirements. These cells meet efficiency and productivity goals.

Explore Welding Services

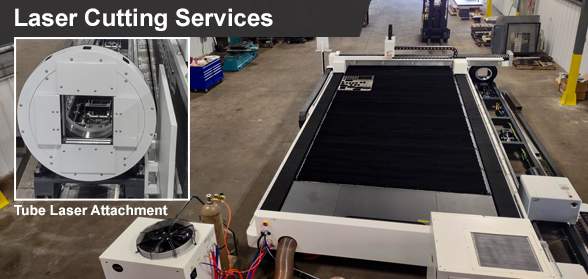

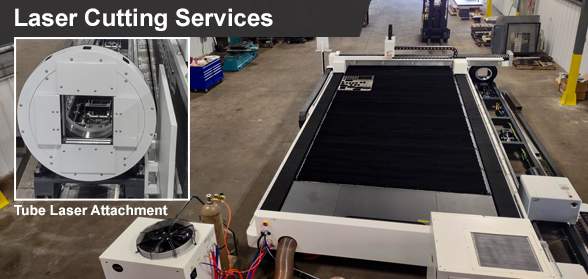

NSMC has access to a wide range of equipment to cut metal depending on the specifications of the part. Our high speed laser can cut up to ¾” thick material on our brand new BODOR AT6 -6000-watt fiber optic laser with an 8’ x 20’ bed and tube laser attachment that can cut up to a 9” diameter tube.

Explore Laser Cutting

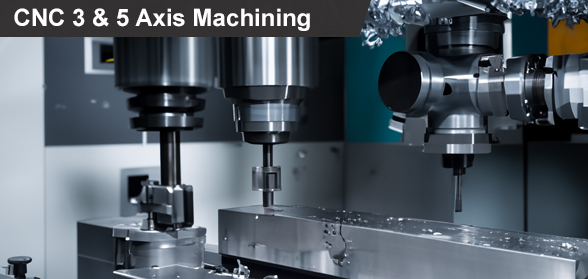

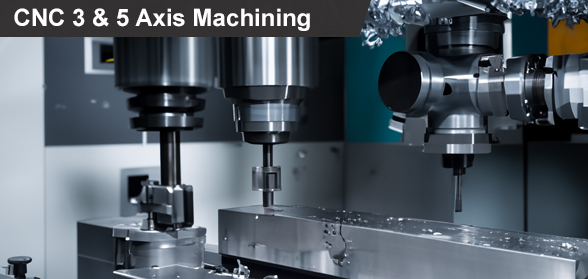

We can machine large and small parts with our 2 CNC Mills that are 3 axis, 2 CNC Mills that are 5 axis, and a brand-new CNC lathe.

Explore Machining Services

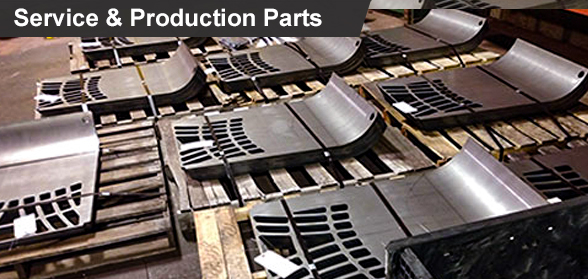

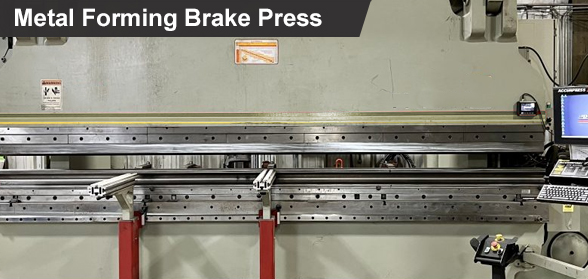

We can do forming work with brake presses and our stamping presses are hand transfer presses. We specialize in service parts and low volume parts.

Our state of the art laser scanner is used for prototyping, quality control, and even reverse engineering. For quality control, it ensures the correct dimensions for the required specification.

We are currently an approved vendor for several manufactures of agricultural, construction, and forestry products and equipment. We also are an approved vendor for several major glass manufacturing OEMs and the US Government. We are looking forward to an opportunity to become a supplier to you as well.